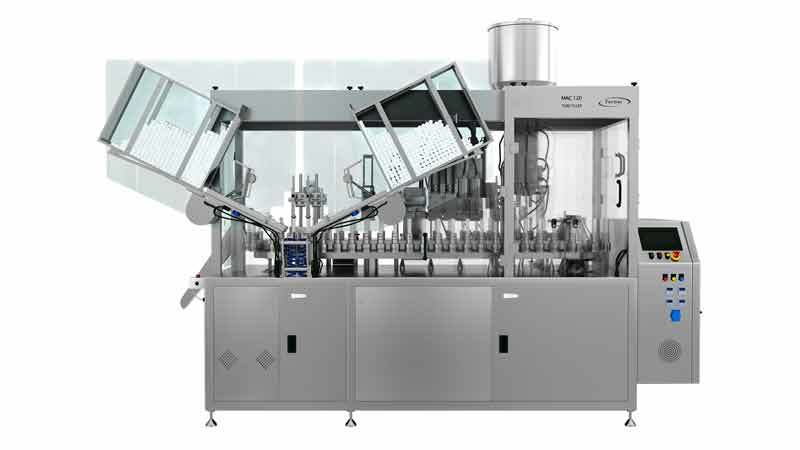

Double Head Automatic Linear Tube Filling and Sealing Machine

Price 190000.00 INR/ Number

Double Head Automatic Linear Tube Filling and Sealing Machine Specification

- Weight

- 2000 Kilograms (kg)

- Filling Capacity

- 5-250 ml Milliliter (ML)

- Sealing Length

- 210mm

- Voltage

- 4500 Watt (w)

- Sealing Type

- Hot Air

- Condition

- New

- Seals Type

- Straight

- Application

- Tube Filling Machine is used for fills of ointment, cream, tooth paste, gel and semi-solid materials in atomic number 13 or in plastic tube and waterproofing of the tube. Application of the machine is in prescribed drugs, cosmetics, foods, adhesive, paint, chemicals et al. industries.

- Color

- Silver

- Automation Grade

- Fully Automatic

- Power

- 4500 Watt (w)

- Sealing Speed

- 120 T/Min

- Type

- Tube Filling and Sealing machine

- Accuracy

- 100 %

- Dimension (L*W*H)

- 2400X1500X3100 Millimeter (mm)

- Driven Type

- Mechanical

- Packaging Speed

- 120 Pieces/Minute

- Packaging Material

- Plastic/Aluminum Tubes

Double Head Automatic Linear Tube Filling and Sealing Machine Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA)

- Supply Ability

- 5 Per Month

- Delivery Time

- 40-60 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Crate

- Main Export Market(s)

- Australia, North America, Western Europe, Central America, Asia, Africa

- Main Domestic Market

- All India

About Double Head Automatic Linear Tube Filling and Sealing Machine

Technical Specification

- Model No:SAF120

- Speed:80 to 120 tubes /min filling capacity

- Volume:3 ml to 250 ml.

- Tube Size dia:11 min to 60 max.

- Tube Size length:50L min to 210L max.

- Power Consumption:4-5KW. Max

- Size of Machine:1300 W X 2400 L X 3100 H

- Net Weight:1600 Kg. (Approx)

- Gross Weight:2000 Kg. (Approx)

Design confirms to GMP Norms.Salient Features:

- Contact parts of SS 316L.

- All operation is fully automatic.

- Sturdy & compact design.

- Tube holders of Nylons.

- Pump unit in Stainless Steel for filling volume choose alternatively one

(1) 5 ml to 10 ml

(2) 2 ml to 50 ml

(3) 3 ml to 100 ml - (4) 100 ml to 200 ml

- Relay Electrical Control Systems.

- Operating panel with START, STOP & INCH.

- 40-50 liters container acid proof.

- No tube No fill mechanism.

- Blow off for connection to local comp. air supply.

- Motor for variable speed.

- Auto Loader of Tubes.

- Cassette Tube in feed system.

- All moving parts are guarded and enclosed.

- Photo-Electric Print Registration.

- Protection Guards.

- One set of tools.

- One set of first aid spares.

Optional Attachment:

- Filling nozzle

- (1)5 to 10ml

(2) 10 to 50ml

(3) 50-250ml. - Stirrer in S.S. hopper

- Jacketed SS hopper, having heat control arrangement with thermostat to maintain the desired temperature.

- Attachment for cleaning of tubes by vacuum system.

- Complete extra pump unit in Stainless Steel.

- Acid proof with pipe connection

- Heater & Temp. Controller.

- Set of Tube holder for diff. dia of tube.

- Vacuum Cleaning Device by compressed air supply.

Sealing & Coding Methods

CAU- 45 M

- Beam with folding stations for metal tubes

- Closure type 1

- Coding device for one side coding with 10 figures.

CAU P

- Heat Sealing Unit

- P/1 Comprising

- C Plain

- Temperature regulator for heating element.

- Mechanical lifting of heating element

- Device for coding one side with 10 digits with trimming of blades.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tube Filling And Sealing Machine Category

Tube Filling Machine

Price 400000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Tube Filling and Sealing machine

Color : Silver

Driven Type : Mechanical

Condition : New

Aluminium Tube Machine

Price 250000 INR / Number

Minimum Order Quantity : 1 Number

Type : Tube Filling and Sealing machine

Color : Silver

Driven Type : Mechanical

Condition : New

Ointment Tube Filling Machine

Price 350000 INR / Number

Minimum Order Quantity : 1 Number

Type : Tube Filling and Sealing machine

Color : Silver

Driven Type : Mechanical

Condition : New

Automatic Double Head Tube Filling Machine

Price 700000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Automatic Double Head Tube Filling Machine

Color : Silver

Driven Type : Electric

Condition : New

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS